ceinture pemasangan compétence pada sistem concasseur POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

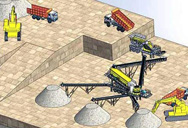

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à contact us pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- installation de concassage et criblage

- concasseur sonbhadra

- chinois de la construction hanqui

- convoyeur de manutention du Calcite plantes

- coût de l'unité de fabrication de l'or coût

- concasseur a cne hpc

- trois laminoir regarder d en haut

- monté cone de concassage à vendre

- capacité des usines de concasseur

- meuleuse béton de poudres

- du ciment du sable de melange stonechips fournisseur de mach

- sociétés de carrières de rechercheéquipement de

- puissance verticla broyeur à cylindres

- station de conksage baioni

- Ball Mill Wet Fournisseur

concasseur vendre zimbabwe

China Wet Ball Milling, Wet Ball Milling Manufacturers,

China Wet Ball Milling manufacturers - Select 2023 high quality Wet Ball Milling products in best price from certified Chinese Milling Machine, China Milling suppliers, wholesalers

Read More

Wet ball mill_Ball mill_PRODUCT_Tongli Machinery

Ball mill can be divided into dry ball mill and wet ball mill. Wet ball mill needs to add water during the grinding process. Wet ball mill can be divided into two types according to its

Read More

Wet Ball Ball Mill China Trade,Buy China Direct From Wet Ball Ball Mill ...

Buy Wet Ball Ball Mill China Direct From Wet Ball Ball Mill Factories at Alibaba. Help Global Buyers Source China Easily.

Read More

MQY series overflow ball mill_Shandong Shankuang

MQY series overflow ball mill-Shandong Shankuang Machinery Co.,Ltd-The ball mill is the key equipment for the material to be crushed and then crushed. Ball mill is one of the

Read More

What Are the Differences Between Dry and Wet Ball Mills?

2021年9月10日 Advantages of wet ball mill: (1) The wet ball mill has better performance and higher grinding efficiency. It has low requirements for ore water content and can

Read More

TECHNICAL SPECIFICATION OF WET BALL MILL

2022年3月29日 The Wet Ball Mill system consists of Wet Ball Mill, Wet Ball Mill Lubrication system, Mill circuit tank with an agitator, Mill circuit Pump, Mill Hydro cyclone, 3-way

Read More

Wet Ball Mill for Metal Ores and Non-ferrous

Buy wet ball mill from trusted wet grinding ball mill supplier. Energy saving wet ball mill, small energy consumption, large productivity, effectively improving grinding efficiency.

Read More

wet milling on sale - China quality wet milling

planetary ball mill. More. We find 600 products about wet milling from 305 manufacturers suppliers. Convex-teeth Corn Germ Stripping Mill a rough crashing equipment for starch

Read More

Wet mill - All industrial manufacturers - DirectIndustry

Find your wet mill easily amongst the 19 products from the leading brands (Liming, NETZSCH, Hosokawa, ...) on DirectIndustry, the industry specialist for your professional

Read More

Wet ball milling of niobium by using ethanol, determination

2021年11月17日 This study investigates the effect of using ethanol as the process control agent during the wet ball milling of niobium (Nb). Dried nanocrystal Nb powders, of high purity, with particle sizes ...

Read More

Ball Mill Ball Mills Wet Dry Grinding DOVE

2023年12月11日 DOVE small Ball Mills designed for laboratories ball milling process are supplied in 4 models, capacity range of (200g/h-1000 g/h). For small to large scale operations, DOVE Ball Mills are supplied in

Read More

Ball Mill - an overview ScienceDirect Topics

Mechanical Crushing and Grinding. Oleg D. Neikov, in Handbook of Non-Ferrous Metal Powders, 2009 Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision

Read More

Prix Factroy Ball Mill Wet /sec l′équipement de Ball Grid Mill ...

Prix Factroy Ball Mill Wet /sec l′équipement de Ball Grid Mill 1200X2400 Prix de vente,Trouvez les Détails sur Ball Mill, petite bille Mill de Prix Factroy Ball Mill Wet /sec l′équipement de Ball Grid Mill 1200X2400 Prix de vente -

Read More

Vibration Feature Extraction and Analysis of Industrial Ball Mill

2015年1月1日 The process parameters used for these experiments of a typical industrial wet ball mill is specified in the Table 1. (a) (b) Fig. 1(a), (b); Position of accelerometer sensors on industrial Ball mill 219 Satish Mohanty et al. / Procedia Computer Science 58 ( 2015 ) 217 – 224 Table 1. Parameters of Industrial Ball Mill Parameters Value ...

Read More

(PDF) Grinding in Ball Mills: Modeling and Process Control

2012年6月1日 A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation. It consists of one or more rotating cylinders partially filled with grinding balls (made ...

Read More

A Review of Alternative Procedures to the Bond Ball Mill

2021年7月12日 It can be performed in any laboratory ball mill, but it requires a reference sample ore for which w i is known. In the Berry and Bruce procedure, 2 kg weight samples of the reference and unknown ores with a particle size under 1.651 mm are wet ground in a laboratory ball mill that is 305 mm in diameter, using active power monitoring.

Read More

Ball Mill - an overview ScienceDirect Topics

8.3.2.2 Ball mills. The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1–1.5 times the shell diameter (Figure 8.11 ). The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

Read More

Minerals Free Full-Text Effects of Ball Size on the Grinding

2019年10月31日 In this study, we investigate the effect of the ball size in a high-energy ball mill on the comminution rate and particle size reduction. High-energy ball milling at 2000 rpm produces ultrafine talc particles with a surface area of 419.1 m2/g and an estimated spherical diameter of 5.1 nm.

Read More

Wear of vibration ball mill in wet grinding at constant

1992年5月1日 Powder Technology, 70 (1992) 153-161 Wear of vibration ball mill in wet grinding at constant temperature T. Yokoyama, G. Jimbo, T. Nishimura and S. Sakai Department of Chemical Engineering, Nagoya University, Nagoya 464-01 (Japan) (Received June 6, 1991; in revised form October 22, 1991) Abstract The characteristics of wear of a

Read More

The effectiveness of wet milling materials in ball mills

2017年8月28日 of the impact of a ball during the "cascade" condition of operating a ball mill by the dry and wet methods. Calculations were made for a ball mill with a diameter of 0.16 m; the weight of the uralite ball was 100 g; its density was 3.15 g/cm ~, and its radius was 2 cm. The viscosity and density of the suspension

Read More

Wet Milling vs Dry Milling: The Differences,

2021年6月17日 HCPS Immersion Mill: this immersion mill utilizes a separately driven sweep blade to ensure consistent product feed to the mill. Micro Mill: the MicroMill goes beyond traditional milling equipment

Read More

A method to identify wet ball mill’s load based on

2021年5月1日 In this paper, a novel method of wet ball mill load identification based on CEEMDAN, RCMDE and SRNN is proposed. Firstly, CEEMDAN-RCMDE is used to extract the load features of the ball mill. Then, taking the advantage of SRNN's fast training speed and strong generalization ability, a mill load identification model based on SRNN is

Read More

Ball Mills Ball Mill Ball Milling - Orbis Machinery

Steel Ball Mills Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800’s. The basic construction of a ball mill is a cylindrical container with journals at its axis. The cylinder is filled with grinding media (ceramic or metallic balls or rods ...

Read More

Ball Mill Loading (wet milling) : 네이버 블로그

2001年10月23日 The starting point for ball mill media and liquid charging is generally as follows: 50% media charge. Assuming 26% void space between spherical balls (non-spherical, irregularly shaped and mixed-size media will increase or decrease the free space) 50% x 26% = 13% free space. Add to this another 45% to 50% above the ball charge for

Read More

Ball Mill Manufacturer - Henan Zhengzhou Mining

2021年7月16日 Ball mill is mainly used for grinding in mining (metallic minerals and non-metallic minerals), cement, refractories, chemical, power plant, aluminum, building material, glass, ceramic, steel slag and fly ash, ect.It follows more crushing and less grinding principle to save energy. The feed size to ball mill shall be smaller than 25mm, the output size can

Read More

(PDF) Kinetics of Fine Wet Grinding in a Laboratory Ball Mill

2001年1月15日 On the other hand, dry ball milling tests were carried out in a laboratory ball mill having a 20 cm internal diameter and 5776 cm 3 volume (Figure 3(b)) with charge of 5475 g steel ball mixtures ...

Read More

Rubber Wear Lining and Protection Weir

Linagard® Wear-Resistant Rubber Sheet. Made from either natural rubber blends, bromobutyl rubber or nitrile rubber, Linagard® rubber sheet is designed to provide superior protection, durability and wear resistance to UV and ozone, chemicals, oils and high temperatures. : Mining, Sand and Aggregates, Infrastructure, General Industry. Wear Lining.

Read More

High-energy ball milling of WC-10Co: Effect of the milling

2022年4月1日 During the first process step, the powders are mixed by ball milling. Different high-energy milling configurations are found in the literature: planetary milling, attritor milling, shaker milling, and high-kinetic rotor milling [5, 6].Table 1 gives an overview of the ball milling conditions in the cemented carbides field. Ball milling can be used for “mechanical

Read More

GitHub

{"payload":{"allShortcutsEnabled":false,"fileTree":{"27":{"items":[{"name":"2004 1100 by 650 cme cme jaw crusher.md","path":"27/2004 1100 by 650 cme cme jaw crusher ...

Read More