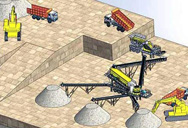

ciment broyage à boulets POUR L’EXPLOITATION MINIÈRE ET L’EXCAVATION DE ROCHE

Notre offre produits propose des solutions pour presque tous types de projets d'exploitation minière et d'excavation de roche. Notre gamme d’équipements et de services pour l'exploitation minière et l'excavation de roche est étudiée afin de maximiser votre productivité et votre rentabilité. Notre expertise se fonde sur des décennies de collaboration avec nos clients et tous nos produits bénéficient de notre réseau mondial pour la fourniture de maintenance sur site, de formation et d’un soutien 24 h/24. N’hésitez pas à contact us pour tout conseil sur le choix d’un produit ou pour un besoin d’assistance technique.

- spécification du convoyeur à vis sans fin horizontal

- herramientas coutume de fraisage

- Broyeur Hydraulique Agricole

- Rock plans de l usine de concassage

- coût de la mise en place d un cas bocard à la clientèle

- lipu china products flotation machine

- fraser concasseur mobile

- minerai à partir duquel le cadmium est à moi

- broyeur de lignite

- concasseur a produire des fines de minerai de fer

- powerscreen turbo Chieftain 1400 especificacões

- pourcentage de sable de concassage dans le bentonite

- fours rotatifs à chauffage indirect et broyeurs

- usine d élution à vendre au Zimbabwe Broyeur inde

- ball mill process variables

concasseur vendre zimbabwe

Comparative Study on Improving the Ball Mill Process

2021年2月19日 The purpose this study is to explore which process variable among the ball mill working capacity, ball mill speed and balls to powder weight ratio have most influential effecct on the particle size of silica sand.

Read More

Ball milling process variables optimization for high-entropy

2023年9月1日 In this study, the influence of ball milling variables (PCA type, PCA amount, ball milling time, and ball milling speed) on the onset of solid-solution, grain size, and

Read More

Prediction of ball milling performance by a convolutional

2022年5月1日 This work proposed a three-phase modelling framework using the convolutional neural network (CNN) method to predict the performance a ball mill based

Read More

Process Control of Ball Mill Based on MPC-DO - Hindawi

2021年7月26日 2. Grinding Process of Ball Mill. In this section, the characteristics of the ball mill grinding process are demonstrated. Then, the controlled variables and the

Read More

(PDF) Grinding in Ball Mills: Modeling and Process

2012年6月1日 A ball mill is a type of grinder widely utilized in the process of mechanochemical catalytic degradation. It consists of one or more

Read More

Investigating grinding mechanisms and scaling criteria in a ball mill ...

2021年8月1日 In our case, the dimensional analysis of the ball milling process will be carried out in order to get a physically meaningful equation between the properties of the

Read More

Disturbance observer based multi-variable control of ball mill

2009年7月1日 Ball mill grinding circuits are essentially multi-variable systems characterized with couplings, time-varying parameters and time delays.

Read More

Model based supervisory control of a ball mill grinding circuit

1999年6月1日 In the present paper the ball mill model, together with the hydrocyclone separation system model is used in a simulation study to generate a response surface

Read More

Application of model predictive control in ball mill grinding circuit

2007年9月1日 Ball mill grinding circuit is essentially a multi-input–multi-output (MIMO) system with strong coupling among process variables. Simplified model with multi-loop

Read More

Ball Mill - an overview ScienceDirect Topics

The ball mill process is a mechanical-chemical process that uses mechanical force to induce the chemical and structural change of certain materials (Amusat, Kebede, Dube, Nindi,

Read More

Disturbance observer based multi-variable control of ball mill

2009年7月1日 Ball mill grinding circuits are essentially multi-variable systems characterized with couplings, time-varying parameters and time delays. The control schemes in previous literatures, including detuned multi-loop PID control, model predictive control (MPC), robust control, adaptive control, and so on, demonstrate limited abilities in control ball mill

Read More

Ball milling process variables optimization for high-entropy

2023年9月1日 Key MA processing variables that determine the final microstructural evolution in alloy particles are the milling -speed, −time, −temperature, − atmosphere, process control agent (PCA), type of mill, ball-to-powder ratio, type-, size-, size distribution- of milling media etc. [49].

Read More

Predictive Controller Design for a Cement Ball Mill

2020年7月26日 Chemical process industries are running under severe constraints, and it is essential to maintain the end-product quality under disturbances. Maintaining the product quality in the cement grinding

Read More

Intelligent optimal control system for ball mill grinding

2017年8月27日 2 Grinding process description The ball mill grinding process is mainly composed of a ball mill, a hydrocyclone cluster, a sump, a slurry pump and an ore bin. The schematic diagram of this process is shown in Fig. 1. Fig. 1 Schematic diagram of ball mill grinding process. The variables of this process shown in Fig. 1 are ex-plained as follows: W

Read More

Effects of two-step high-energy ball milling process and hot

2022年5月6日 Commercial powders of magnesium were processed by high-energy ball milling (HEBM) using a two-stage composite process. The microstructural and morphological evolution of the powders was studied using scanning electron microscopy (SEM), energy-dispersive spectrometry (EDX), and X-ray diffraction (XRD). From the results obtained, it

Read More

Control of a closed dry grinding circuit with ball mills using ...

2022年12月1日 Closed circuit dry grinding using ball mills is essential in mineral processing industries. This process is characterized by significant dead times, highly coupled variables, limitations by operating ranges and complex modeling, making it difficult for classical controls to obtain fast responses with low overshoot.

Read More

(PDF) Controlling the Ground Particle Size and Ball Mill

2023年9月23日 Grinding in a ball mill is a process with high energy consumption; therefore, a slight improvement in its performance can lead to significant economic benefits in the industry.

Read More

(PDF) Predictive Controller Design for a Cement Ball Mill

2020年9月15日 Predictive Controller Design for a Cement Ball Mill Grinding Process under Larger Heterogeneities in Clinker Using State-Space Models September 2020 DOI: 10.3390/designs4030036

Read More

Prediction of AG/SAG Mill Variables from Surface Vibrations

2006年1月1日 The process state of an AG/SAG mill can be inferred from surface vibration monitoring. This is a passive, non-intrusive, low cost and reliable hardware monitoring technology that is sensitive to ...

Read More

Mechanical Milling: A Superior Nanotechnological Tool for Fabrication ...

2021年9月24日 Mechanical alloying (MA) is a typical solid-state process that occurs at room temperature between powders of diffusion couples utilizing various types of ball mills. Ball milling has evolved over the last five decades from a standard technique in mineral dressing and powder metallurgy, where it was primarily used for particle size reduction

Read More

Materials Development Using High-Energy Ball

2022年6月17日 High-energy ball milling (HEBM) of powders is a complex process involving mixing, morphology changes, generation and evolution of defects of the crystalline lattice, and formation of new phases. This

Read More

Calculating breakage parameters of a batch vertical stirred mill

2017年9月1日 The standard breakage function developed by Broadbent and Callcott, has been successfully used for ball mill modelling and simulation (Napier-Munn et al., 1996).This breakage function is extensively used, such as in the perfect mixing ball mill model in the JKSimMet mineral processing simulator (JKTech, 2012).The selection function shows the

Read More

Model based supervisory control of a ball mill grinding circuit

1999年6月1日 The overflow is the desired product. The underflow is recycled back to the ball mill for further grinding. The product size is specified as 80% passing 200 mesh screen. The controlled variables in this process are the circulating load and the product size. Two manipulated variables are available, the solids feed rate and water addition rate.

Read More

Prediction of ball milling performance by a convolutional

2022年5月1日 1. Introduction. Ball milling is a critical process to reduce product size into a desired size range, which has been widely used in industries such as minerals processing, cement manufacturing, pharmaceutical industries and powder metallurgy [1, 2].The milling process is affected by many parameters, including ground particles, mill speed [3], milling

Read More

ResearchArticle ProcessControlofBallMillBasedonMPC

2021年7月26日 variables,whicharefreshorefeedrateu 1,dilutionwater feedrateu 2,andmillfeedwaterfeedrateu 3,respectively. e relationships among all the variables and distur-bances in the ball mill system are introduced briefly in Figure2. ese three controlled variables and three manipu-lated variables are completely determined by process

Read More

Model Predictive Control - Rockwell Automation

2021年3月31日 recovery process. Different configurations of SAG, ball and rod mill occur but in general a SAG mill can be considered an intermediate stage in breaking down rock from the crushing plant, and feeding to ball or rod mills for further size reduction. Types of mill Different types of mill are in operation e.g. rod or ball mills, so

Read More

Constrained model predictive control in ball mill grinding process

2008年8月1日 The grinding process studied in this paper operates in a closed loop as shown in Fig. 2, including a ball mill and a spiral classifier. The feed, iron ore (from primary crusher, size ≤ 14 mm) is fed into the ball mill by swaying feeders. Download : Download full-size image; Fig. 2. Process diagram of grinding process.

Read More

Predicting the effect of operating and design variables on

2013年4月1日 Perhaps the greatest relevance of understanding relationships between design and operating variables and mill performance is in developing scale-up rules, from which the performance of industrial mills can be predicted using data collected from tests conducted either in batch laboratory or continuous pilot-scale mills. Two of the most well ...

Read More

A Dynamic Ball Mill Model for Process Control - LinkedIn

2023年6月20日 The First-Order Plus Dead Time Process Model. The most commonly used model to describe the dynamics of a process is the First-Order Plus Dead Time model (FOPDT). Although higher order models do ...

Read More

Efficient preparation and characterization of graphene based on ball ...

2022年12月1日 Table 2-1 factors and levels were combined in a homogeneous design with a total of five influencing factors in the experiment: X1 — ball mill rotation rate, X2 — aluminum powder particle size, X3 — aluminum mass, X4 — steel sand mass, and X5 — steel sand particle size. According to the principle of uniform design, the number of trials

Read More